1.2 billion people in the world live without life’s most basic human need–shelter. However, at the recent 2018 SXSW festival and conference, the unveiling of the first permitted 3D printed home in America could make global homelessness a thing of the past. New Story, a non-profit that builds houses for people in developing nations, and Icon, a construction technologies start-up company in Austin, Texas, came together at the famous Austin festival to demonstrate that it’s possible to build a low cost, easy-to-replicate, single-story 800-square-foot house in only 12 to 24 hours, a fraction of the time it takes for new construction. This dynamic duo plan to take this proof-of-concept into its next phase by producing small houses for families in countries like Haiti and El Salvador.

How is this possible?

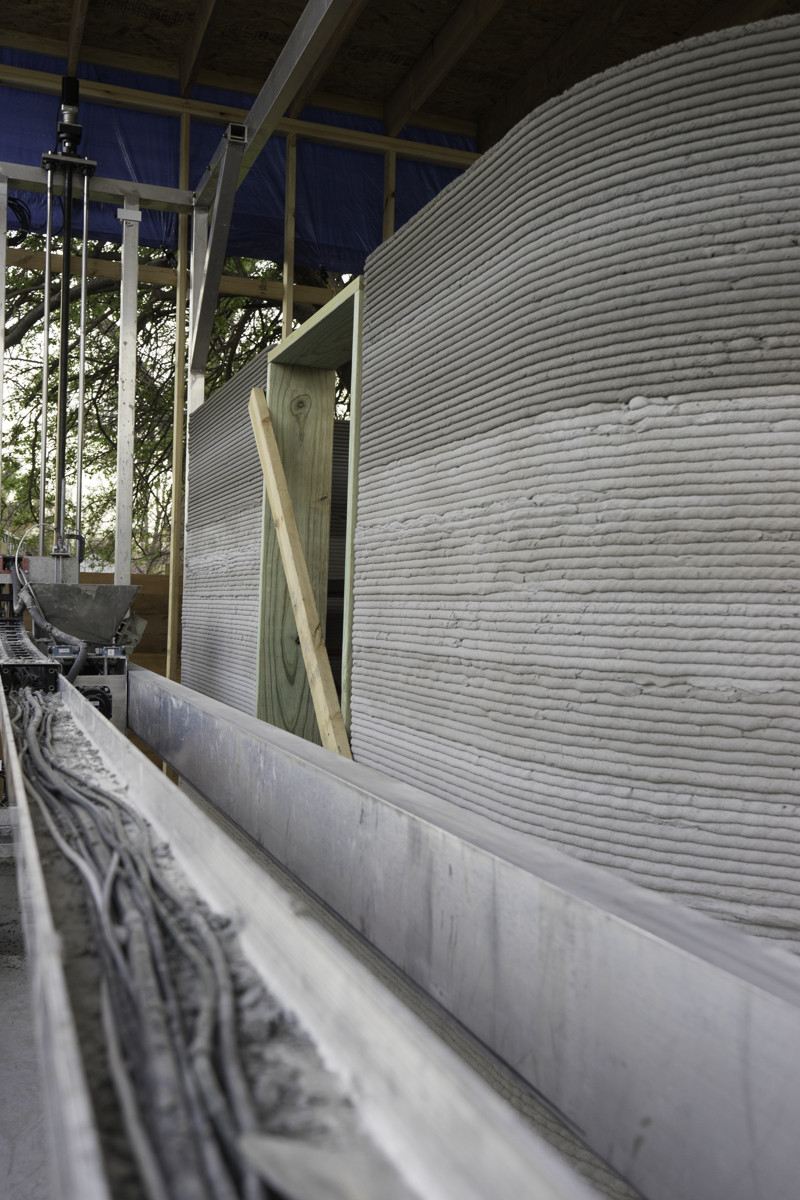

Right now, the 800-sq-ft house costs around $10,000 to build using Icon’s portable Vulcan printer. However, the company plans to get the cost down to $4,000. Each house has a living room, bedroom, bathroom and a bonus room (which can easily be transformed into another bedroom.) The modest size can easily accommodate a small family. One of Icon’s three founders, Evan Loomis, stated in a recent Quartz interview, “The printer excretes a custom blend of concrete that hardens as it’s printed. The concrete is laid in 100 roughly one-inch-thick strands that hold their shape as they harden. The strength of the printed walls is stronger than cinderblocks after a few days of hardening, although the house is entirely habitable after it’s been set up.”

Credit: Icon

Credit: Icon

Credit: Icon

The Process

In under a day, the Vulcan 3D printer creates the wall with 100 lines of concrete and then the New Story crew members do their magic by installing: windows, basic plumbing, a wooden roof, and electrical wiring drilled right into the walls. Down the road, Icon hopes to create robots that could automatically install the windows and would also like to utilize drones to spray-paint the exterior walls. They also hope to investigate the possibility of printing roofs as well, but the technology for suspending concrete while printing isn’t quite there – yet. For now, these houses are long-term solutions designed and built to stand the test of time, even natural disasters.

The Vulcan 3D Printer. Credit: Icon

The Future

Icon has plans for its house-printing technology and production to be utilized in the US, especially where housing shortages are high. They will continue to develop revolutionary, cutting-edge materials tested to the most recognized standards of safety, comfort, and resiliency and to design homes with nearly zero waste production methods. Ultimately, Icon wants to lead the way into the future of homebuilding by using 3D printing to make major advancements in affordability, building performance, sustainability and customizability.

Leave a reply